*The term Basic and Basic + PLC in the configuration selection does not refer to the Dobot Magician Basic robot arm. The term Basic refers to the training station available without the robot arm.

A training system package that provides you with the best of the robotics knowledge base with various accessories and a detailed user's guide to their operation.

What the best of knowledge base means?

Tricolor lamp

First and foremost, the tutorial system allows us to use the most important element of the robotic arm and workflows. Status feedback is an essential part of any industrial application, allowing us to monitor the current status of our robotic arm's work, the physical position or quantity of material being processed, or the system's response to external intervention. The lamp, which has three different colours, can be used in a variety of ways when it comes to the communication solutions that are essential for its operation. The first chapter of this user guide covers the operation of the tricolour lamp, in which we will learn about the possibilities offered by the add-on in Python programming language and block-based programming.

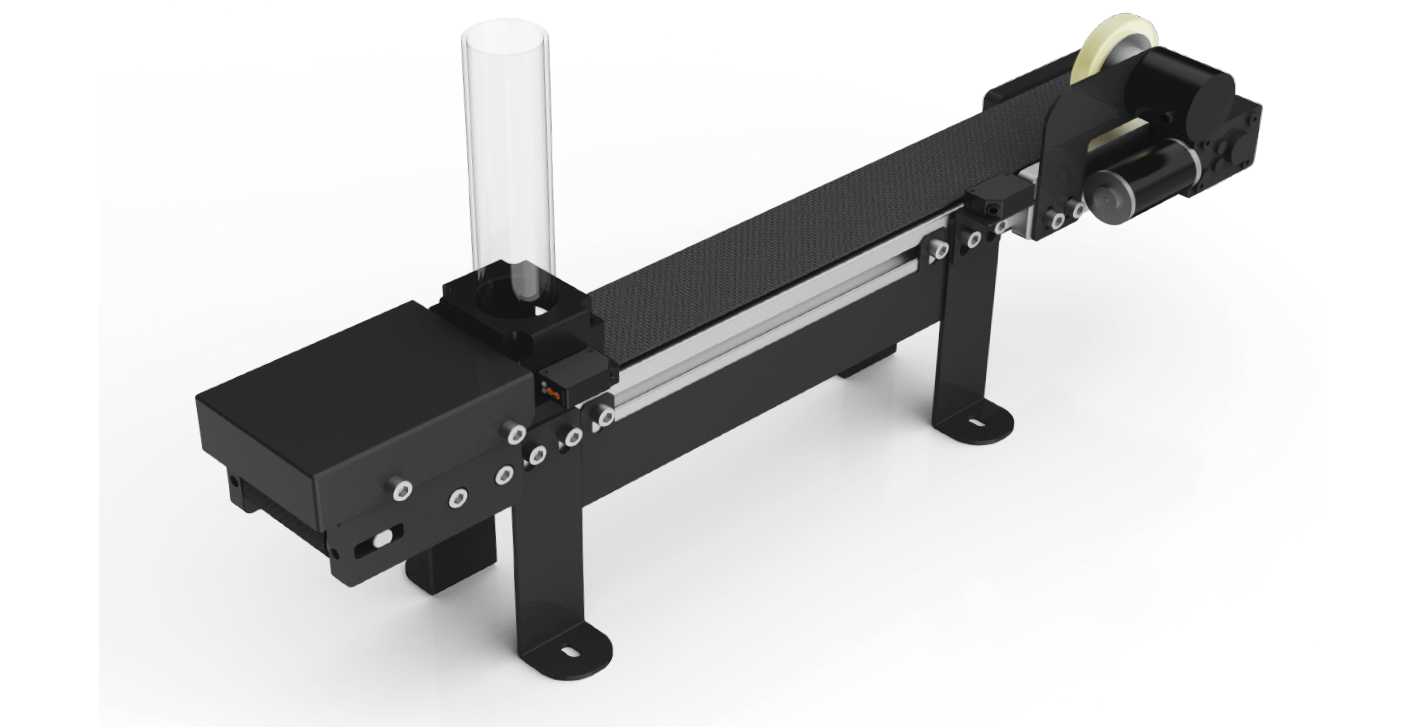

Conveyor belt unit

As a target solution for logistics applications and industrial automation challenges, the conveyor belt unit supports our work with built-in storage, raw material feeding add-ons and adjustable speed. Its application also covers palletising, sorting or simple in-feed control processes, which are necessary yet complex logistics solutions for industrial automation applications. The three chapters of the user guide also cover palletising, static and dynamic sortation and controlled assembly automation processes, where the easy-to-integrate conveyor belt offers an even more advanced solution.

Visual unit

In quality control, smart manufacturing and many applications of Industry4.0, image processing units that enable our equipment to make decisions as autonomous units have become essential. With the help of a visual unit, the robot arm can perform static and dynamic sorting tasks after a simple calibration. But its greatest advantage is in controlled assembly processes, where the automation technologies of a manufacturing process can be learned by assembling a chip system of a telephone. The process also covers block-based programming and a detailed description of a key program that can be written in Python.

Toolkit

An important accessory for assembly and maintenance work are the target tools that allow you to assemble the right combination for the job without damaging screws and other parts. The set therefore includes a screwdriver, allen key, calibration needle, vacuum-operated end tool, screws and connectors.

A vacuum source unit is essential for the operation of vacuum-operated grippers to ensure the operation of the end tool.

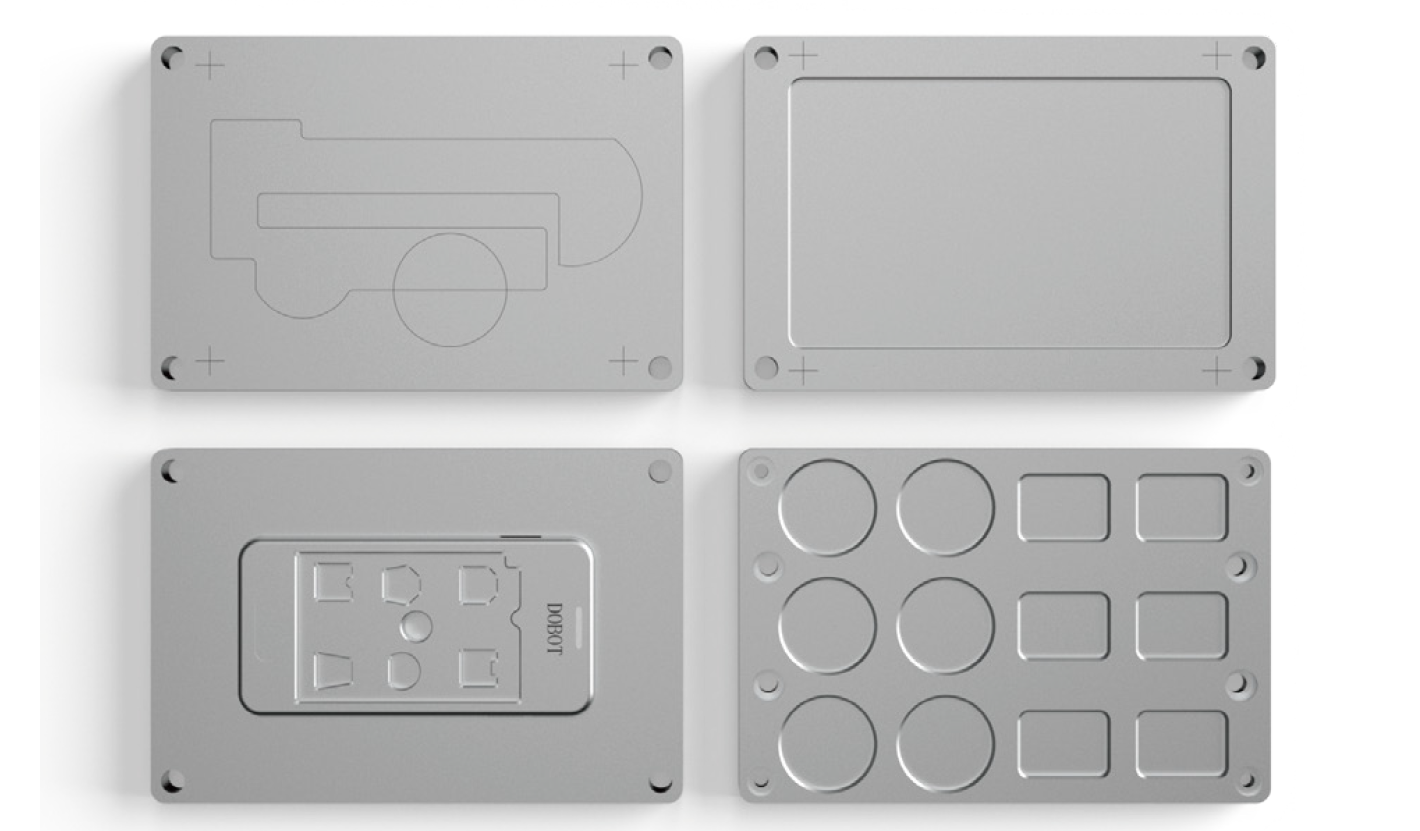

Quick change plates

These aluminium bases serve as platforms for various applications, so that automation processes can be implemented in a laboratory environment.